Our Products

- Surface

- Material

- Design

- KOS®

- KOS ROOT®

- BCS®

- ZSI

- TPG® uno

- TPG®

- Hexacone®

- S-System

- Bone Level Plus®

- Xign®

- Implant Accessories

No-Itis® Laser

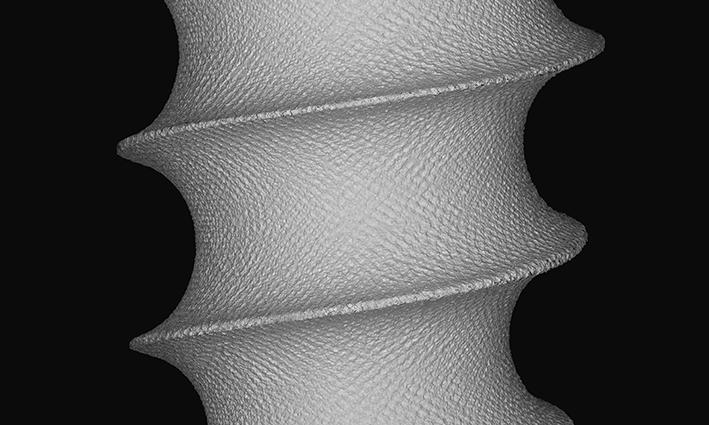

The Innovative Surface Generation

The surface treatment for Dr. Ihde Dental AG implants is created with the latest generation of robotic tools for laser ablation. This technology of high precision creates roughness in the implant through a mesh of hemispherical micrometric pores, with a defined, always identical size and shape and with a symmetrical distribution.

The result is a more adequate topography, which provides the most suitable conditions for the osseointegration of the implant, but at the same time it is, and behaves like, a smooth surface at a micrometric (cellular) level. This means that while bone grows well on this surface, the adhesion of bacteria to the same surface is significantly reduced.

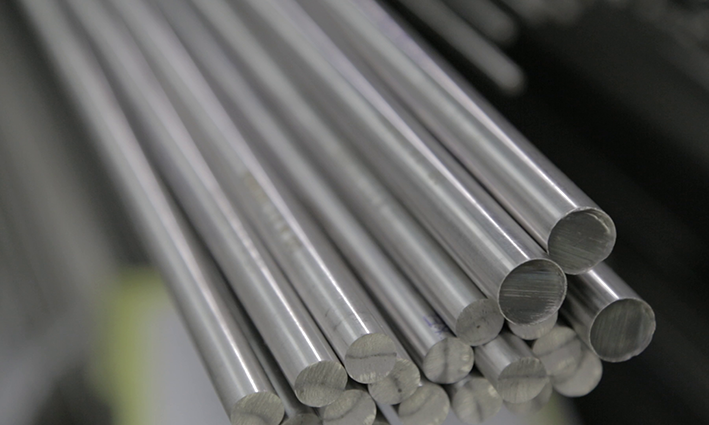

Ti6AL4V ELI

Our implants are made of Ti6AL4V ELI, also known as „Grade 5“. This is the high-purity version of the conventional 6/4 Ti alloy, which is used for more than 50% of all metallic human implants. This material is the first choice for all applications which require high stability, corrosion resistance and mechanical strength. This is why today‘s most modern dental implant designs are made of this material. This titanium alloy is superior to the alternatively used pure titanium in terms of stability by more than 25%. Also regarding biocompatibility and the support of bone cell growth, this titanium alloy shows advantages compared to pure titanium.

Design

The shape of our implants always follows the design principle "Form follows function". The bone does not have to adapt to the implant through interventions such as bone augmentation, instead the implant can be selected and inserted according to the existing bone supply.

Thanks to the wide range of our implant systems, we can ensure that you will find the right implant for each of your patient cases.

KOS®

KOS® implants are suitable for crowns, bridges and bars. With the correct surgical procedure and good bone quality, the compression screws design permits to incorporate the restoration in an immediate loading protocol (incorporation of the prosthesis within a maximum of three days). Today, KOS® implants are routinely used for immediately loaded bridge constructions. The single-piece design saves costs, effort and prevents the problem of screw loosening. In extraction cases, KOS® and BCS® are combined.

KOS ROOT®

KOS ROOT® implants are used for crowns, bridges and bars. The compression screw design permits to incorporate the restoration in an immediate loading protocol (incorporation of the prosthesis within max. three days). The single-piece design reduces costs, the danger of periimplantitis and it eliminates the hazzles of screw loosening. KOS ROOT® implants are straight with prosthetic head for cementation.

BCS®

BCS® implants can be used immediately in extraction sockets if the basal support is sufficient. The anti-rotation protection ensures immediate stability against unintentional unscrewing before prosthetic loading. The prosthesis should be inserted before the 3rd post-operative day. BCS® implants are used typically for segments and circular bridges in an immediate splinting protocol. Their use is permitted only for authorized users.

ZSI

ZSI implants are inserted either trans-sinusally (between the membrane and outer bones) or submucosal in the lateral upper jaw and anchored in the area of the Os Zygomaticum. In this case, the smooth parts of the implant are submucosal.

These implants are only used by experienced practitioners with a good knowledge of anatomy. ZSI implants have a bending area below the cementing abutment and can therefore be inserted into the dental arch according to the axis even after palatal insertion into the upper jaw. A separate vertical osteotomy may be necessary for this. See scheme. In one-sided free-end situations, it can be combined with one or more BCS® implants in the area of the tubero-pterygoid region.

The treatment should be carried out in immediate loading protocol. Immediate splinting of the implants is necessary.

TPG® uno

TPG® uno implants provide a sharp and cutting central thread part, which engages in to the corticals of the extraction sockets. The apical compression thread provides perfect stability both in compressed spongious and in cortical bone. The coronal micro-thread seals the 1st cortical if the implant is used in healed bone areas. TPG® uno implants may be used both in extraction sockets and in healed bone areas. They are used for circular bridges and segments. Under adequate loading conditions and if enough implants are splinted, the treatment can be performed in an immediate load protocol. Due to their polished surface, TPG® uno implants are extremely resistant against bacterial colonialization and they avoid periimplantitis. TPG® uno implants are not designed for single implant reconstruction.

TPG®

TPG® implants provide a sharp and cutting crestal thread, which engages in to the corticals of the extraction sockets. The apical compression thread provides perfect stability both in compressed spongious as well as in cortical bone. A wide range of abutments is available.

TPG® implants may be used both in extraction sockets and in healed bone areals. They are used for circular bridges and segments. Under adequate loading conditions and if an excellent primary stability is achieved, the treatment can be performed in an immediate load protocol. TPG® implants can be used in combination with other compression screw implants (e. g. KOS®) the basis of fixed prosthetics.

Hexacone®

The traditional Hexacone® implant shows safe anti-rotation through the high precision internal hexagon. The apically expanded bone thread ensures excellent stability in all bone qualities. Hexacone® implants are suitable for universal use for fixed and removable prosthetics. The cone ensures abutment alignment and 100% tightness.

Hexacone® with aggressive apical thread: HC2

As a result of many years of clinical observation of products, Dr. Ihde Dental AG has revised the design of the famous Hexacone® implant: the broadened apical thread is fully self-cutting. Thanks to the new apical thread portion, the implant is more stable even in weak bone and higher insertion torque can be reached. HC2 implants with aggressive apical thread have a roughened endosseous surface. They feature an internal hex, an internal marginal taper and a US standard internal thread.

S-System

SSO® is a successful implant with octagon socket and 8° inner cone for rotationally-secured suprastructures. The surface is roughened in the endosseous region.

STO® is a precision conical implant with octagon socket and 8° inner cone. Compression screw thread for stable endosseous anchorage. For rotationally-secured suprastructures.

STW® implants with internal octagon and 8° inner cone are for anti-rotation super-structures.

Bone Level Plus®

Bone Level Plus® implants possess an internal square for anti-rotation that connects with press-fit to the abutment. The cone in combination with the internal stare provides stability and 100% tightness. Bone Level Plus® implants are universally applicable for fixed and removable prosthetics.

Xign®

The Allfit® implant system Xign® is designed for enossal dental implantations. Xign® implants feature two high-precision internal cylindrical guides and hexagon. Implants with diameter 3.0 and 3.4 mm are not indicated for single tooth replacement. The Xign® implant system is suitable for dual-step implantation protocols. Xign® accessory parts are colour coded.

Implant Accessories

Matched to the respective implant system, we offer you a wide range of high-quality and well thought-out instruments.